Swiftech MCR220QP G1/4" Radiator Review

Introduction

Welcome to my review of the Swiftech MCR220QP, this happens to be a radiator I traded another forum member for and used it as my third chipset loop. Just like it's bigger brother the MCR320, the 220 exhibits the same slim style radiator optimized for low speed fans targeted at the mainstream market segment where users want high performance without breaking the bank.

Before going into details, I'd like to give a special thanks to Gary from Sidewinder Computer Systems Inc. for sponsoring my latest computer upgrade, a quad core Q6600. After I complete a few more these radiator tests, I plan to switch over to CPU block testing on this new quad core processor. Sidewinder Computers is quickly becoming my favorite place to shop. Not only are they typically the lowest priced online retailer, they also ship extremely fast and have exceptional customer service. I would highly recommend you giving Sidewinder a visit on your next water cooling upgrade!

With this review I plan to cover radiator characteristics, hydraulic restriction, and thermal performance with a wide range of fans. I'll follow my typical engineering/technical flavor and keep the commentary to the point. In the end, I hope to provide you with some tools to help you design your water cooling system with this radiator. My ultimate goal is to help you better understand how heat load and fan selection affects the performance of this radiator as well as hydraulic restriction.

Here is my lightly used MCR220 that was tested, it does exhibit some chipped paint that occurred in both of my radiators. Paint quality is lacking and easily chipped. Some of the premium radiators like the TFC and HWlabs radiators are much better with paint quality and finish.

Radiator Characteristics

The radiator is a slim style, open finned radiator optimized for lower speed fans. Here are some characteristics I noted:- Single Row, Dual pass flow

- Top plenum chamber is specially shaped to minimize trapped air and self purge.

- 12 Brass Tubes and Chambers (One more tube and row than some radiators)

- Copper Louvered Fins (Standard louvers internally to increase turbulence)

- G1/4 Threads

- 282mm x 128mm x 34mm (L x W x H)

- I measure approximately 14.1 folds per inch average, (Frontal length is 9.25" with 130 folds).

- Standard built in shroud of approximately 1/4" depth. - This is common to almost all radiators these days.

The fins are a good open density, although the consistency in spacing is poor. Some areas are more dense than others as you can see in the above photo which is worse than your typical premium style radiator. I don't think this hurts performance much at all, but it doesn't portray much attention to detail that you would recieve in more premium priced radiators.

Hydraulics and Pressure Drop Testing

The most scientific way to determine a blocks hydraulic resistance is to test pressure drop. Pressure drop is a measurement of pressure loss across a radiator that varies with flow rate. This is basically a measurement of energy loss, and directly influences how much flow rate you will have.

- Dwyer Digital Manometer 477 Mark V - Accuracy .5% of Full Scale. Range 0-20.00 PSI range, Resolution .01 PSI

- King Instruments 7520 Series 0-5GPM, 250mm scale - Accuracy 2% of Full Scale. Range 0-5GPM, Resolution .1 GPM (can be interpolated to .02GPM)

- Water Source - Household water pressure - 50PSI at >5GPM - Because flow rate readings are instantaneous, household tap water and water pressure are a good and powerful source for pressure drop testing.

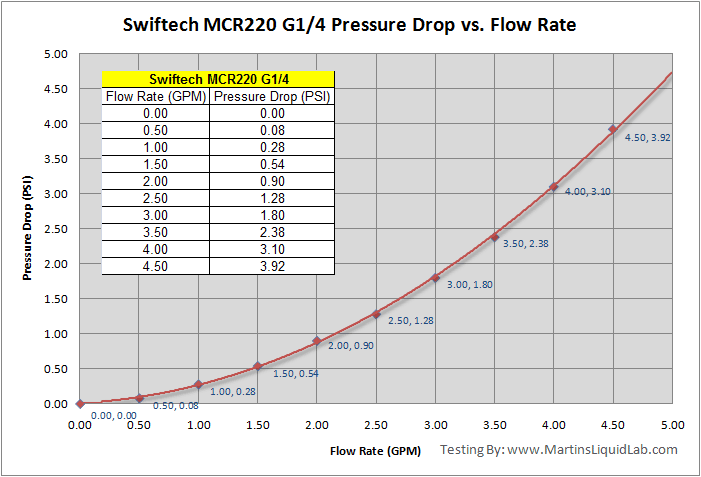

Here is the raw data collected.

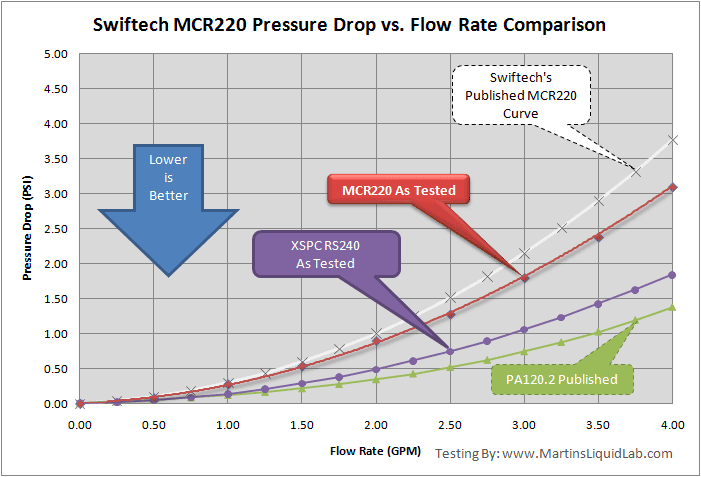

And here it is compared to a few other sources and one other double radiator I tested, the XSPC. I also measure less restriction that was published on Swiftech's site, but reasonably close. I used a more standard high flow D-Tek barb in this testing.

Thermal Testing Specifications

I followed the same testing specs as outlined here, except I elected to only test at the 300 watt level heat load.Thermal Testing

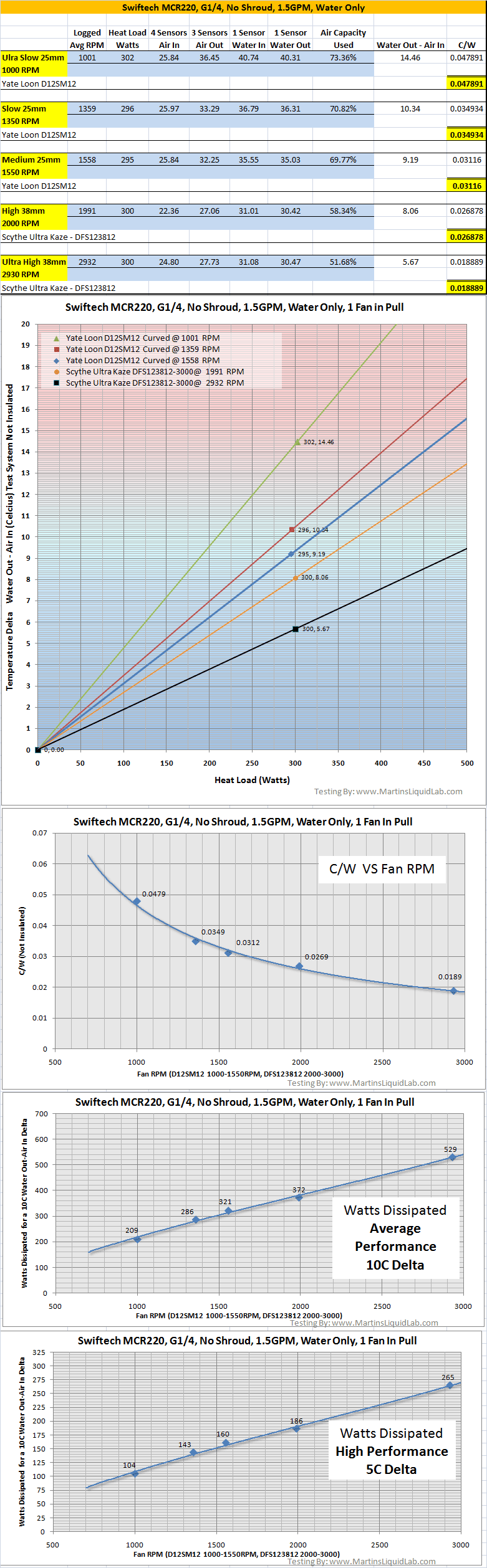

So, after 5 individual 30minute warm ups and 30minutes sessions of logging temperatures, these are my results:

- Extreme Outer Visions PSU calculator - Just note heat load minus the 38 watts included in the start.

- Swiftech's Conroe/Kentsfield CPU calculator - This is actual an estimator for the kit, but it also gives what I think is a more accurate heat load for the processor. Just plug in the field and it will output a heat load in watts.

So what does this water temperature mean? You are cooling with the water that leaves your radiator and enters your CPU block. So any improvement in this number will directly translate into an improvement in your CPU temperature. For example if your water temperature delta is 10C and your loaded core temperature was 50C. If you improved your water delta by 5C either by adding another radiator or increasing your fan performance, your new core temperature will be 45C assuming your ambient temperature remained the same.

Just to run through some options/design. A single overclocked dual core processor can dissipate around 125 watts of heat between cpu and pump, so in that case an MCR220 would be capable of delivering a high performance 5C delta with fans at only 1200RPM, this would be a nice silent setup. However on a quad core, you would need more substantial fans for that level of performance where you would need something in the 2000RPM range.

For a CPU/GPU combo, you'll likely only manage 10C or what I'm calling average water cooling performances. These aren't bad, they just are not extreme. For something like 300W setup with a dual core and 8800GTX card, you could get average performance with about 1500RPM.

Something like a 570Watt quad core plus 8800SLI setup couldn't be done under a 10C delta even with the 3000RPM ulra Kazes, I would recommend something larger or addition radiators

Thermal Performance Calculator Download

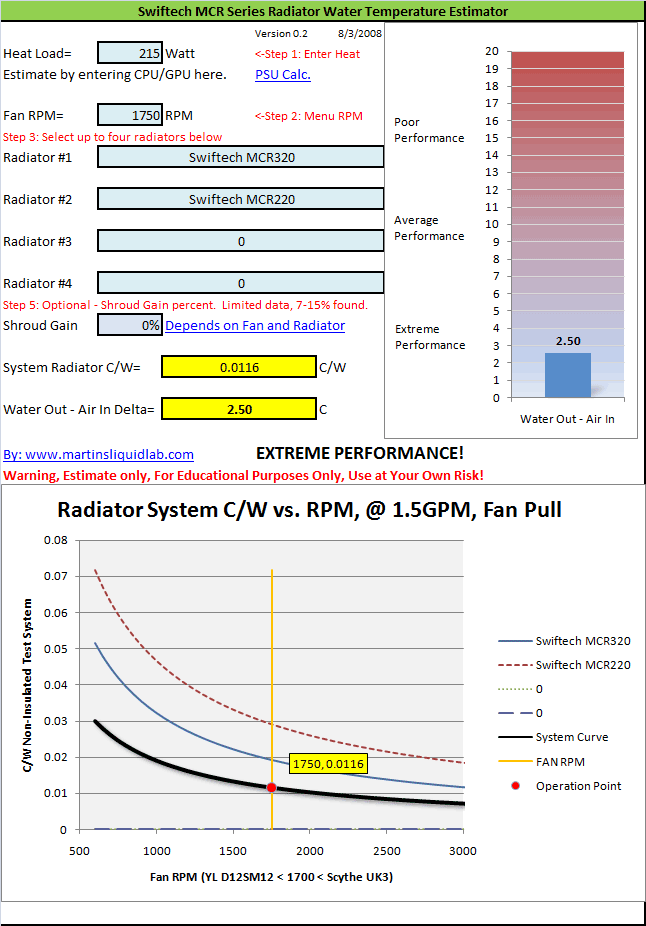

If the above charts are confusing, no worries, I've figured out a way to take that data and create another calculator for you. This estimator provides you a means to estimate your water delta based on your actual heat load, fan RPM, and even provides a shroud boost option. Furthermore it allows you to estimate the heat using more than one radiator and mixes of sizes that I've tested. So far, I have only included my tested MCR220 and MCR320 results.The estimator looks something like this:

- For Educational Estimating purposes only

- Use at your own risk!

Pros

- Good value, high performance/low cost!

- Optimized for lower speed fans

- Plenum chamber shape bleeds quickly

- Thinner size will allow more flexibility in installation options

Cons

- Not as efficient as the high end model radiators, particularly ultra high speed fans.

- Black paint is easily chipped

- More restrictive than similar models may add up in muliple radiator setups

- Fin consistency and density varies (Irregular fin spacing)

Bottom Line

The MCR220 is really a good all around performer at a great price. It does exhibit a few quality issues like the poor paint bonding and irregular fin spacing/density, but for those willing to overlook these things and get really great thermal performance at low prices, this radiator is an excellent option.Where to buy

Sidewinder Computer Systems MCR220 Direct Link