Radiator Thermal Testing Specifications

Introduction

Rather than continue to copy and past the same testing specifications and clutter other pages, I've decided to detail out my method for testing radiators here.

But before I do that, I'd like to thank the following sponsors in my testing:With all of this, I'm able to get a pretty good and accurate understanding of how you can estimate performance depending on the fan used and generate some decent information. Below are some more details and links of the radiator testing equipment used:

Radiator Testing Specifications:

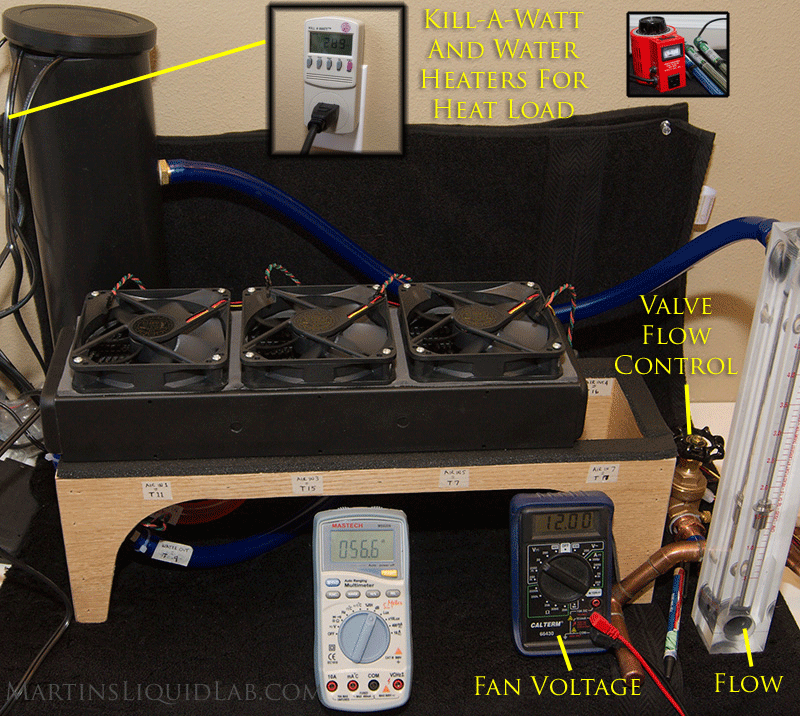

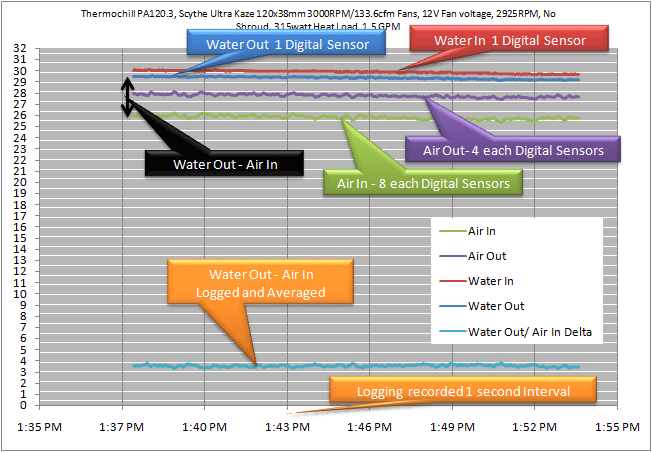

- Thermal Temperature and Fan RPM Monitoring - CrystalFontz CFA-633 32 Channels of temperature, 4 channels of fan RPM, Logging Capability in CSV format exportable to excel, .5C absolute accuracy. Used to log 14 individual temperature sensors and one fan RPM sensor to log results at 1 second intervals. Here is a small data example of what just one run looks like which is logged in the below chart, thankfully the Crystalfontz does most of the work for me.

- Thermal Sensors - Dallas DS18B20 Digital one-wire sensors. .5C absolute accuracy overall with a .2C mean error between 20-30C.

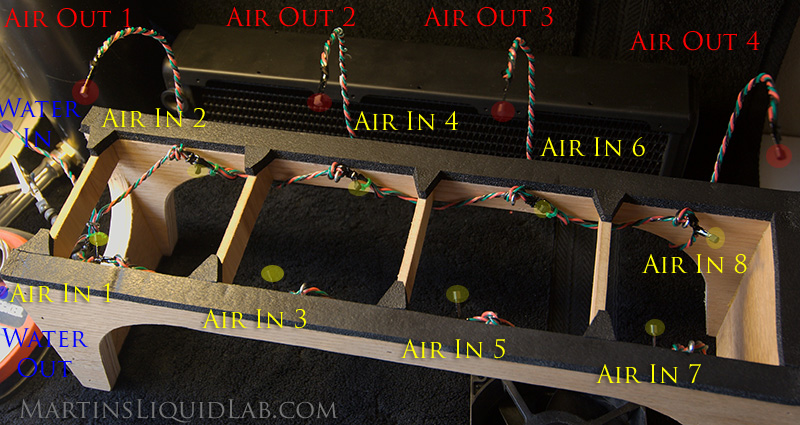

- Test Bench Sensors Deployed -

- 6 each air inlet sensors, two for each 120mm fan section (2 sensors are used for every fan section of radiator, 2 for a 120, 4 for a 240, etc.)

- 4 each air outlet sensors, 1 for each 120mm fan section (1-2 sensors are used for every fan section of radiator).

- 1 water inlet sensor

- 1 water outlet sensor

- Custom Test Bench - Custom built 120mm x 4 radiator test bench with permanently mounted sensors to improve consistency and minimize setup time.

- Flow rate - King Instruments 7520 Series 0-5GPM, 250mm scale - Accuracy 2% of Full Scale. Flow rate is controlled via 3/4" brass gate valve to precisely 1.5GPM. Flow rate effects are generally minimal in radiators so I have selected 1.5GPM as a good average flow rate point.

- Water - I used regular filtered tap water for testing purposes.

- Warm-up - Each fan configuration is allowed to reach temperature for 30-45 minutes until equilibrium is met. This is determined by recording and logging of temperatures for at least 1 hour and only averaging the results that are found after equilibrium is obtained.

- Fans and RPMs tested:

- Yate Loon D12SM12 120mm x 25mm - 70.5cfm/1350 RPM/33 db (open air)

-

- Ultra Slow Speed Fans - Undervolted to 1000 RPM

- Slow Speed Fans - Undervolted to 1350 RPM

- Medium Speed Fans - Voltage adjusted to 1550 RPM

- Scythe Ultra Kaze DFS123812-3000 - 136cfm/3000 RPM/45.9 db (open air)

-

- High Speed Fans - Undervolted to 2000 RPM

- Ultra High Speed Fans - Voltage adjusted to 2930 RPM

- Logging of Temperatures - Each temperature sensor and fan rpm channel is logged for 30 minutes to both average out any temperature fluctuations and also to ensure the system has stabilized and heat loads/fan RPMs remained constant during the testing period. If temperatures did not fluctuate or an error occurred, the test was thrown out. Over a 30 minute period data for all 14 temperature sensors and fan header are recorded every second producing a data matrix of 1,800 entries over each channel.

- Air Inlet Temperature Data - Each test averages the 8 inlet channels (6 in the case of a triple radiator), and then average over the testing period of 1,800 results. So Air In can be the average of up to 8 x 1800 = 14,400 data points collected.

- Water Outlet Temperature Data - Water outlet data is also captured by the same Dallas sensor with an average of 1,800 data points collected.

Typical Test Logging for Each Fan Scenario and Heat Load

- Water - I used regular filtered tap water for testing purposes.

- Warm-up - Each fan configuration is allowed to reach temperature for 30 minutes minimum prior to recording and logging of temperatures. I found that it takes around 15minutes to reach equilibrium when deltas are in the 5C range, and up to 45minutes for deltas of 15C.

- Open Environment Testing - I also wanted to note, that I am not insulating the coolant lines, my flow rate meter, or my reservoir, so the c/w values I generate are for the complete system. I am using about 6' of 1/2" ID by 3/4" tubing, a 14" King Instruments flow meter, a 3/4" brass gate valve, and at tall 4" diameter by 24" tall reservoir which do loose some heat during testing. Initially I had thought about insulating my system, but the more I've thought about it, a regular water cooling system also looses heat through tubing and reservoirs, so I think it's an acceptable heat loss that is similar to normal water cooling systems. I also have and will continue to test every radiator exactly the same, so they all have these same heat loss advantages through the test system. The one variable I can't fix is the ambient temperature changes, and there is some differences in thermal properties of air as it changes. I think they are probably small enough to keep my results within 5% or so, but it's still something I don't have control over where an environmental chamber would be ideal.

Radiator Testing Sponsors

The following sponsors made my testing possibly by donating various parts, fans, and radiators for testing. Please visit their sites in appreciation, thanks!