XSPC X2O Delta CPU V2 Waterblock Flow Testing

Introduction

Welcome to my pressure drop testing of the XSPC X2O Delta V2 for a wide range of processors. This page will focus on the pressure drop and flow characteristics only for this waterblock only.

Block Characteristics

The block is a finely CNC machined block. The base is a 49.2mm circular solid copper base with very very fine diagonally cut square micropins. There is a large number of pins (over 1000! according to XSPC). I was pleasantly suprised to see the pins up close, they are very well machined for such fine and difficult thin cuts, all of this will result in a very large heat transfer surface area which is good. The top is a machined brass all metal top with a chrome finish and the XSPC logo "X" depressed within. I really like the unique look it gives and the all metal construction ensure long term durability.

The base has a very nice mirror finish as you can see. You might be wondering...were are the screws? The copper base and brass top are finished to zero tolerances and press fitted together. Fortunately this is a simple two layer block, so cleaning should be relatively easy by removing the barbs and accessing the barb entrys. This does however mean, it would be very difficult to dissassemble the block for a detailed cleaning, but I think in general most users will be fine with flushing the block from the entry points as that's likely where any system debris would stop as well.

But before we finally proceed to testing, how about a macro of those pins...The following is a look down one of the G1/4 barb holes for scale. Now that's what I call "Micro Machining" very nice!

But before we finally proceed to testing, how about a macro of those pins...The following is a look down one of the G1/4 barb holes for scale. Now that's what I call "Micro Machining" very nice!

Delta V1 vs Delta V2

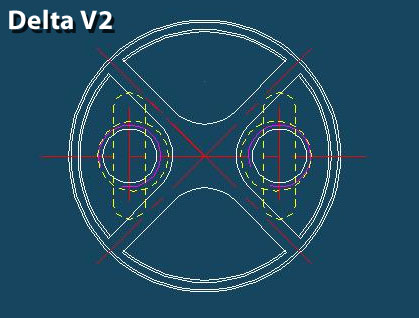

The block revision between delata 1 and 2 is a fairly simple one. V1 had a relatively simple cirulcar barb entrance and V2 added in a channenl cut into the barbs that spreads the flow over a great area of the pins. First here are some internal pictures provided to me by XSPC of the V1 opened up. You can see the relieve cut into the top was cirlces that were just slightly larger than the barb openings.Delta V2 added another set of cuts that run up and down and distribute the flow over the base. Here is a drawing that XSPC provided to me that helps explain that.

Hydraulics and Pressure Drop Testing

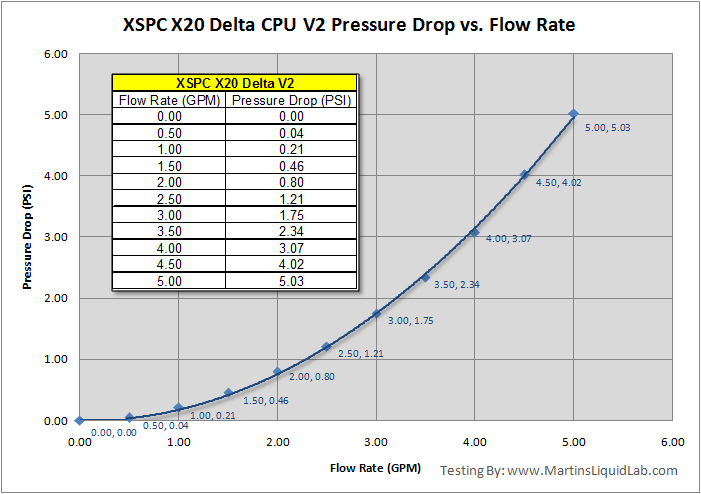

The most scientific way to determine a blocks hydraulic resistance is to test pressure drop. Pressure drop is a measurement of pressure loss across a block that varies with flow rate. This is basically a measurement of energy loss, and directly influences how much flow rate you will have.Equipment:

- Dwyer Digital Manometer 477 Mark IV - Accuracy .5% of Full Scale. Range 0-20.00 PSI range, Resolution .01 PSI

- King Instruments 7520 Series 0-5GPM, 250mm scale - Accuracy 2% of Full Scale. Range 0-5GPM, Resolution .1 GPM (can be interpolated to .02GPM)

- Water Source - Household water pressure - 50PSI at >5GPM - Because flow rate readings are instantaneous, household tap water and water pressure are a good and powerful source for pressure drop testing.

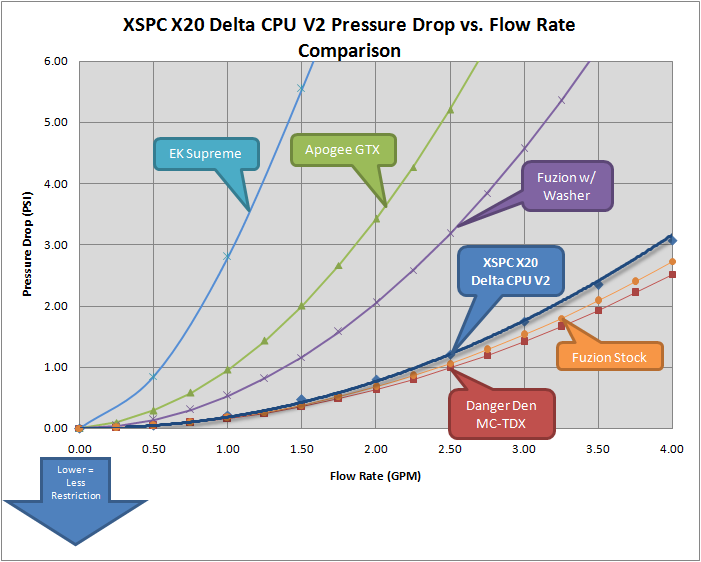

And if you're not familiar with what this means, I'm providing a relative chart below with several CPU waterblocks. It is particularly important to have low pressure drop when installing multiple block loops because every block in that loop creates restriction and too much on any one block can potentially reduce flow rates enough to influence performance on the rest of the system. So too much restriction can mean less performance on other blocks and the radiator dissipating the heat.

The XSPC X2O Delta V2 has excellent flow rate characteristics. It nearly ties the Danger Den MC-TDX for being the least restrictive micropin style CPU block, very impressive! It appears the very large and tall pins are providing a very large array to distribute flows and reduce resistance.

The XSPC Delta CPU V2 block is an extremely free flowing block with minimal pressure drop!

The flow rate characteristic for the XSPC X20 Delta CPU V2 is exceptionally good and nearly the best I've tested to date for a micropin CPU block. This will enable users to utilize the block in multiple block loops with very little impact to flow rate. Excellent!!

Where to buy

XSPC Retailers Link