The Feser Compancy X-Changer 120.3 Radiator Pressure Drop Flow Testing

Introduction

Welcome to my pressure drop testing of the "The Feser Company" X-Changer 120.3 radiator. I would like to give special thanks to Jeremy from Danger Den for loaning me this radiator for a quick flow rate pressure drop test. I know it's a hot topic on the forums and glad I could test it for pressure drop.

With this review I will focus on the pressure drop and flow characteristics for this radiator.

Radiator Characteristics

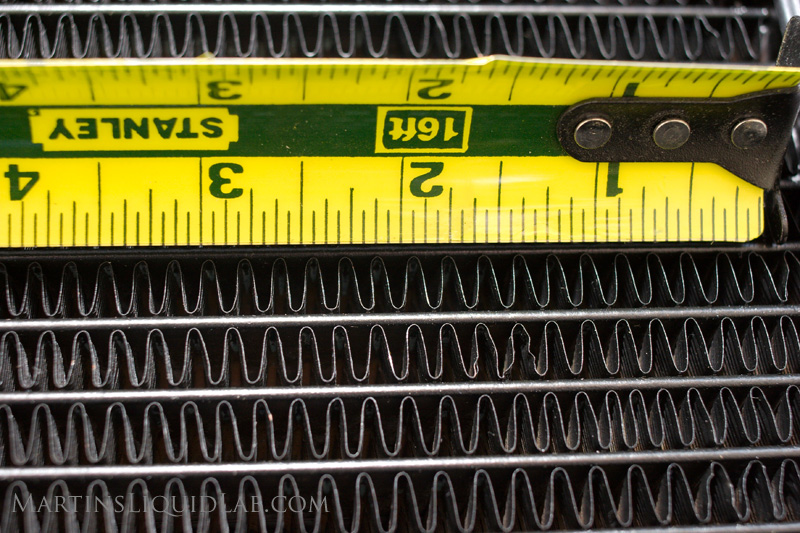

The radiator is a very thick and open finned designed to be optimized for low speed fans. It has similar thickness and fin structure to that of the popular Thermochill PA 120.3. Here are some characteristics noted by the manufacturer.- Water Channels and Fins made out of ECu Copper Material

- Brass Water Chambers

- Black Finish (5µm)

- G1/4" Threads

- Bleed Valve Screw

- 411 x 123 x 62 mm

(L x W x H) - Approximately 11-12 folds per inch

Prototype Only

I should note there will be some slight exterior type changes still going on here, so the final production model will be a little different. I heard they may be working on the threads, different paint, and some shroud ideas. So it sounds like very minor exterior changes only.Hydraulics and Pressure Drop Testing

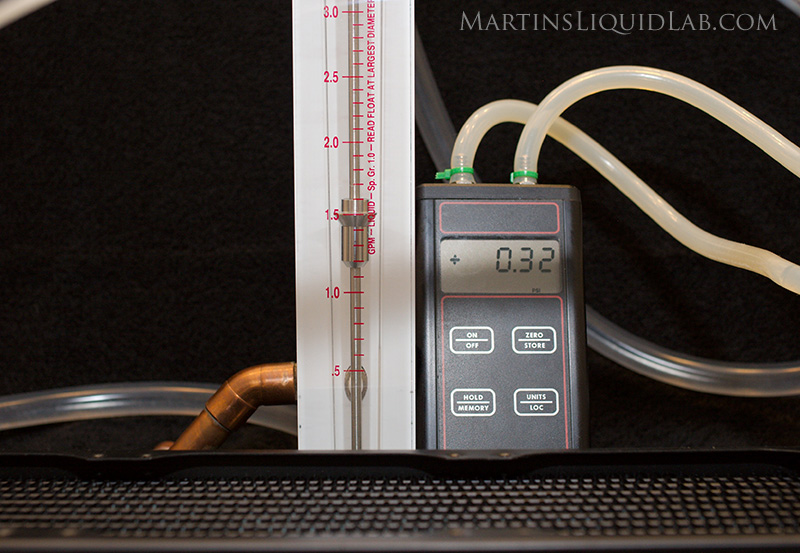

The most scientific way to determine a blocks hydraulic resistance is to test pressure drop. Pressure drop is a measurement of pressure loss across a radiator that varies with flow rate. This is basically a measurement of energy loss, and directly influences how much flow rate you will have.

Equipment:

- Dwyer Digital Manometer 477 Mark V - Accuracy .5% of Full Scale. Range 0-20.00 PSI range, Resolution .01 PSI

- King Instruments 7520 Series 0-5GPM, 250mm scale - Accuracy 2% of Full Scale. Range 0-5GPM, Resolution .1 GPM (can be interpolated to .02GPM)

- Water Source - Household water pressure - 50PSI at >5GPM - Because flow rate readings are instantaneous, household tap water and water pressure are a good and powerful source for pressure drop testing.

Update 3-22-08, I've acquired a new Thermochill PA120.3 on loan from the great folks at Danger Den to complete this comparison. Special thanks goes to Dennis and Debbie at Danger Den for making this happen. I tested the PA with the same setup, and because the PA comes in G3/8" barb threads I first tested with some EK G3/8" barbs, and then some G3/8" to G1/4 reduces from Watercoolingshop.com to use regular barbs. I then used the Danger Den Fatboy G1/4 barbs on those adapters for my second test. In the end, both radiators had very similiar and very low pressure drop.

The Feser X-Changer 120.3 has exceptionally low pressure drop, very impressive!

I'm very impressed with the X-Changer's low pressure drop and I'm very curious how well it does thermally with the copper channel construction. Copper tubes are generally not used in radiator design because copper is very soft, brass provides greater structural strength. But Feser found a way to utilize copper (better thermal conductivity than brass) tubes and I can only expect that will help with thermal results. I have no doubt it will perform very well!

Where to buy

Danger Den